Oxford Said Business School, October 31st 2018

The dinner took place in the West Wing of the Said Business School, also known as The Thatcher Business Education Centre, which was completed in 2013. It was a break from our usual choice of venue where we try to make a link to the grandeur of our Victorian industrial heritage, compatible with the image that Bessemer evokes. The new-fangled West Wing building had a security system to prevent unauthorised entry, not surprisingly since the MBAs apparently pay up to £3000 a day to attend courses. This delayed the smooth passage of our guests, but may have increased their sense of anticipation. Will Bessemer dinners ever be so high class that they need high security? Hopefully not. The entry rigmarole didn’t detract from the success of the evening anyway.

Aim of evening

The dinner aimed to make the connection between the discovery at Oxford University of the cathode material which launched the rechargeable and portable battery revolution for consumer electronics, with the advent of electric vehicles which takes battery technology to the next level. The first time around the UK was unprepared for the electronics revolution which followed. This time around industry and government appear to be much more ready for it. We wanted to understand this better, and leading on from our very successful Compound Semiconductor Dinner in Cardiff in September, to underline the importance of a ‘sovereign’ supply chain capability.

Linked Up

As the theme of the evening was linked to electrification, there was a valuable continuation of the debate we held in Cardiff around Compound Semiconductors, which was reinforced by the participation at the dinner of several members of the South Wales community. The context for both dinners was the electrification of transport and the management of the energy grid. This meant we had wider participation than we would have had for a purely battery event, and in addition others attended because they had an interest in the wider electric vehicle supply chain.

Gathering of the tribes

Also interesting was that we had members from every part of the UK attending. They came as wide and as far away as Scotland, the South Coast, Newcastle, and the Cornish borders, in addition to Oxford, Cambridge, London and the Midlands. As one member put it, we are bringing the different tribes together. The value of this intermingling is it helps to achieve a cross-fertilisation of ideas, interests and opportunities, together with new connections. Indeed, this is a hallmark of a Bessemer Dinner.

Keynote Speakers

Rob Millar: Head of Electrical at Williams Advanced Engineering Ltd, based at Grove near Harwell.

Neil Morris: CEO of the Faraday Institution, based at Harwell.

Dr Graeme Purdy: Founding CEO of Ilika plc, based near Southampton.

Oxford University’s Place

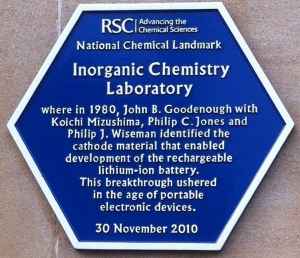

The blue plaque outside Oxford University’s Department of Chemistry recognises the invention of the rechargeable lithium-ion battery.Some of those who were part of the research group in 1980 continue to play a leading role in battery research at the University. This has been rewarded by the fact that Oxford is the largest recipient of Faraday Battery Challenge research funding among universities.

The blue plaque outside Oxford University’s Department of Chemistry recognises the invention of the rechargeable lithium-ion battery.Some of those who were part of the research group in 1980 continue to play a leading role in battery research at the University. This has been rewarded by the fact that Oxford is the largest recipient of Faraday Battery Challenge research funding among universities.

SELF-INTRO SPEAKERS

Each Bessemer Dinner has a 2-minute self-intro session for selected members and guests.

All attention as the Self Intro Session gets underway.

Christoph Birkl, CEO and Co-Founder of Brill Energy Ltd, intelligent control system for batteries that extends cell life, spun out from Oxford University.

Ben Masheder, Collaborations Manager at DST Innovations Ltd, developing novel LEDs with interest in printed photovoltaics, printed supercapacitors and printed batteries, based in S Wales.

Ian Balchin, Chairman of Rapid Powders Ltd, manufacturing polymer-composite powders for Additive Layer Manufacturing, now also addressing batteries, based in Stoke on Trent.

James Simester, from Unipart, currently involved in a 50:50 joint venture to manufacture batteries with Williams Advanced Engineering.

Jean de La Verpilliere, founding CEO of Echion Technologies, a spinout from Cambridge University, developing fast charging lithium anode cells.

Martin Boughtwood, founder of Deregallera Ltd, based in Cardiff, which is working on sodium ion cells and supercapacitors to extend battery life.

Sai Chivareddy, Director of Talga Technologies Ltd in Cambridge, the technology development arm of graphite mining company, Talga Resources.

Kevin Brundish, CEO of AGM Batteries Ltd., in Thurso, Scotland, the largest independent battery manufacturer in Europe, and member of the Faraday Challenge Board.

Sam Evans, Director, Newport Wafer Fab Ltd, one of the largest compound semiconductor fabs in Europe, acquired from Infineon AG by a local business consortium.

Andy Sellars, Business Development Director at the Compound Semiconductor Applications Catapult, Cardiff.

SELF-INTRO SPEAKER GALLERY

Speakers create expectation by giving a short introduction to what they are doing and what they want to contribute to or expect to receive from the evening.

- Christoph Birkl – Brill Power

- Ben Masheder – DST Innovations

- Ian Balchin – Rapid Powders

- James Simester – Unipart

- Jean de La Verpilliere – Echion Technologies

- Martin Boughtwood – Deregellara

- Sai Chivareddy – Talga Technologies

- Kevin Brundish – AGM Batteries

- Sam Evans – Newport Wafer Fab

- Andy Sellars – Compound Semi Catapult

- Paul Blackmore – Warwick Manufacturing Group

Graeme Purdy – Ilika plc

Graeme going out to bat for innovation…

Graeme was appointed CEO when Ilika spun out of the University of Southampton in 2004. The company then listed on the AIM market in 2010. Ilika is typical of a Bessemer company that has had to battle the short term expectations of investors who want exciting new technology to reach profitability faster.

Its proprietary high throughput combinatorial technology accelerates materials discovery. Initially, its principal customer was Toyota Motors. The first Toyota Prius used a nickel-metal hydride battery, but when Toyota launched the Mark II Prius using lithium ion it worried about fire risks, especially after the recall of Sony’s laptop computers and other high profile incidents, such as the fire on Boeing’s Dreamliner. Ilika has been helping Toyota’s search for a solution using solid state technology under an agreement which allows both parties to file joint patents. This agreement gives Ilika freedom as well to carry out its own development work, including working with other car companies.

About three years ago Ilika introduced its own brand of micro batteries, Stereax®, designed for medical and long-life industrial IoT applications. More recently it has been adapting its technology for electric vehicles using a different process platform for large cells. It is now one of a host of companies receiving generous funding under the government’s Faraday Battery Challenge.

Ilika is participating in two Innovate UK projects: One is to improve the design of batteries for high performance cars, which is led by McLaren; the other is a 30-month project which Ilika is leading, involving the Centre for Process Innovation (CPI), Honda UK, Ricardo and UCL. The aim is to develop a solid-state Stereax® battery which can charge in under 25 minutes; to establish a pre-pilot manufacturing line; and processes for a solid-state materials supply chain. Graeme added they expect to be successful.

Graeme noted there is some scepticism about whether solid state batteries will be commercially successful. A recent report by IDTechEx, for example, noted that early investors had been burnt; but mentions three venture-funded companies which have achieved very high valuations. Graeme concluded therefore that the future is still very open.

One question Graeme is often asked by investors is whether now is a good time to invest in batteries? He pointed out that cell manufacturing has always been dominated by high volume manufacturing companies in Asia and is now commoditised. Even so, he believes that demand for EV cells will outstrip supply as we enter the next decade and that there is profit to be made for domestic suppliers of both high quality “traditional” li-ion cells and for next-gen solid state batteries.

Neil Morris – The Faraday Institution

A lively talk underway…

The Faraday Institution is a pillar of the Industrial Strategy’s Batteries Challenge Fund.

Neil took up the position of CEO in July and is off to a fast start. Previously he spent nearly 30 years at BP, then moved in 2014 to lead a privately-owned refinery and oil trader.

The fact that he was responsible for collaborations with universities as director of technology at BP probably helped him to secure the role at the Faraday, as well as his experience of leading a small company.

The Faraday Challenge is looking at all types of battery technologies and battery applications but the most important area for these now is electric vehicles. The motor industry employs around 170,000 people directly and 700,000 indirectly which makes it a very strategic industry. The Domesday Scenario would be if electric vehicles were made elsewhere, said Neil; the Optimistic Scenario would be if battery companies establish Giga factories in the UK and the industry could employ even more people than the current car industry.

The economic and political sensitivity of the EV transition therefore is why the Faraday Battery Challenge is at the heart of the government’s new Industrial Strategy. Its total funding of £246mil makes it the largest single Industry Challenge programme. This is shared between the Faraday Institution, the Battery Industrialisation Centre (BIC-UK) and Innovate UK to fund collaborative projects.

The Faraday Institution’s role is to improve the way world class research at UK universities best meets the needs of industry and the development of a world class EV supply chain. Initially it has selected four research themes for funding: battery modelling, battery degradation, recycling, and solid state technology. The watchword is collaboration, with typically 4-5 universities involved in each programme.

Neil explained that they are adopting a ‘fail-fast’ approach to ensure “the most buck for the money”. If a research programme hits on something important more funding will be made available. The aim is to create a step change which puts the UK ahead of the world, and to avoid the fate of the rechargeable lithium ion battery, invented at Oxford University and licensed to Sony with hardly any value added to the UK. This time must be different.

Rob Millar – Williams Advanced Engineering

Rob gives an industry perspective..

Rob has had a lively career in and around F1 including several years running his own electronics company, R&D Vehicle Systems. He joined Williams Advanced Engineering as Head of Electrical and Battery Systems in mid-2016 and was a member of the interview panel when the Faraday Institution was formed, making him feel very much a part of the organisation; on which he serves as an Expert Panel Member.

Electric vehicles are currently the key market for batteries, a huge market with great future potential – having said this, he is careful of hype. The Scottish government’s plan for example to go electric by 2032 (ahead of England) seems challenging given the population distribution of Scotland.

The infrastructure to service the population is as important as manufacturing and selling batteries. In cities, for example, where people live in apartments he expects autonomous vehicles, which are booked not owned, to become the typical mode of transport. They will be electric and charged at parking locations around or outside cities. For long distance travel the issue will be how to handle the amount of energy required given that a large service station may need 1MW or more of power capacity, equivalent to a micro power station. One solution is to store and discharge power to the grid from the batteries when cars are parked using a vehicle-to-grid power management system. But there are numerous other solutions currently being looked at.

Aircraft too will require a huge amount of power, demanding in the region of 15kW/kg from battery cells compared with say a Tesla which is about 700W/kg. Some Formula-E racing cells can achieve such energy density but only for a short burst. Even so, he believes aerospace companies are serious about electrification and therefore solutions will be found.

Williams Advanced Engineering (WAE) was the sole supplier of the battery systems to the race teams for the first four Formula-E seasons, it therefore has huge experience in battery management in the most demanding environments. Given this heritage Rob explained companies are keen to seek its help to solve problems. One example is a project for Airbus who have have developed a ‘pseudo-satellite’ aircraft with a 30m wing span, which can remain at high altitude for up to three months. The aircraft is powered by batteries with very high gravimetric energy density (Wh/kg) which is not obtainable through standard chemistries such as NMC or NCA.

Another of its customers, Aston Martin, is launching its first electric car, the Rapide E, next year. [Initially, only 155 examples of the electric saloon will be built and first customers will take delivery in 2019; manufacture will be in South Wales in a purpose built facility]. Williams have deliverd a battery providing full power through the SoC range. This solves the problem that many EV batteries tend to deliver high power for short periods but then become temperature limited due to the design of the cooling system. He can’t let on though how they did it! Manufacture of the batteries will be in a new facility that Williams have formed as a joint venture with Unipart, called Hyperbat. It will combine Williams’ design expertise with Unipart’s knowledge of manufacturing and logistics to deliver up to 10,000 batteries a year.

The electric vehicle is a platform for many other technologies. Pulling these together must also be a key consideration for the Faraday Challenge which will migrate away from an Automotive only focus over time. F1 heritage companies like Williams are particularly strong at bringing technology together from a number of fields.

Picking up on Graeme’s point about investing in the battery industry, Rob had recently visited some of the Giga factories in China. His view is that the Chinese are able to build in very large volumes because they are not encumbered by the restrictions imposed by having to justify the business case to a finance house. Through (effectively) state sponsorship of their efforts they are confident that there will be a market if the price and quality are right as they are building capability in advance of sales in the knowledge that they will come.

THE FUTURE: THE RAPID-E ASTON MARTIN (WITH WILLIAMS INSIDE)

The Rapide E will be powered by an 800V battery electrical architecture with 65kWh installed capacity using over 5600 lithium ion 18650 format cylindrical cells. Range target is over 200 miles. Projected top speed is 155mph.

It aims at maximum performance on-demand at the same level as would be expected from a conventional internal combustion-engined car. This includes the ability to drive a full lap of the Nürburgring course with no derating of the battery and the ability to cope with the daily demands of repeated hard acceleration and braking.

DISCUSSION PERIOD

To acknowledge the role of Oxford University in the history of the battery, I gave the floor first to Andy Gilchrist, who is responsible for the University’s Industrial Research Partnerships in the Energy sector, including batteries.

Research at Oxford University

We learnt that there are over 180 Professors involved in some form of energy research, and over 20 actively involved in battery research. The research on batteries is in four main areas: basic chemistry (how compounds behave and interact), materials (new materials and understanding their behaviour in batteries), devices (new battery technologies) and systems research (how devices perform in systems and what systems require from batteries).

We learnt as well that the University’s Oxford Energy Network is developing multi-disciplinary understanding for future low carbon energy systems, which involves researching as well new regulatory requirements, business models, user requirements and how to trade energy in order to understand where value can be added and by whom. Among other things they are looking at how centralised systems will evolve and how decentralised systems (e.g. in Africa) will grow (analogous to the telcomms leap they made).

Common elements

The broad overview of Oxford’s engagement with the energy sector led to a discussion about the infrastructure for electric vehicles. Iain Mosely (whose previous company Converter Technology was acquired by Charge Point this year) commented that wind/solar can store energy locally at the home to charge a car overnight; a traditional service station in a fairly remote location can have battery storage onsite to allow for rapid charge without the cost or expense of grid reinforcement (i.e. the battery allows the grid to supply the average power level with the batteries providing a bi-directional buffer); and batteries can help to maintain power frequency during periods of light or heavy loads on the grid. He pointed out that all these applications also needed to use Power Electronics (in which Iain specialises) “which provide the ‘glue’ to connect the systems to the grid with the minimum of energy wastage.”

Grid capacity issue

The challenges to the grid were pointed out by a member who believes the grid is near capacity on many days (visit the National Grid Website he said). Exacerbating this is a trend to shut down power stations, so where will the surplus energy come from he asked? On the demand side, he calculated that battery-run electric buses consume 2.5 kWh per km. Based on 400km per day this would be 1,000 kWh/day (1MWh/day per bus). For the UK bus and coach fleet of 50,000 that amounts to 50, 000 MWh or 50GWh per day, or the equivalent of 2.1 GW continuous power. Meanwhile UK Grid Peak Demand is currently 40GW. He suggested therefore that the Faraday needs to look carefully at investing in a high voltage network to replace the current low voltage system.

There was then a debate about whether there was going to be too little capacity available on the grid. One member had assumed that there would be a significant problem, while another said there was a case to argue that the grid would have surplus capacity. Another said estimates about future demand needs varied between 0.8 of current capacity to 5 times the current capacity. [The Japanese experience after the Fukushima nuclear accident when all nuclear power stations were closed for over a year does imply that there is resilience in networks to cope with higher demand, but…]

Energy Storage

One member thought that the government may have focused up to now on automotive in part to provide incentives for the auto industry to stay in the UK after Brexit. As a result of this little attention had been paid to grid scale storage, where the focus is on cost, reliability and safety, rather than on weight. As the share of renewables continues to grow, storage will be more necessary to manage frequency fluctuations caused by weather. Currently the way this is managed is complicated by the contracting relationships between suppliers and the grid. The member suggested modest incentives or legislative change by the government could help unlock this.

Investment

A member whose company is developing a novel copper-zinc battery chemistry suitable for large scale energy storage pointed out the difficulty of funding for IP rich, capital intensive start ups that need between £2mil to £10mil Series A financing. It is a “huge gap in the market which needs to be plugged”, he said.

Jacqui Murray, Deputy Chair of the Faraday Challenge, recognised the difficulty of making investment decisions when there are so many variables and unknowns. She cited the decision by the TerraE Consortium in Germany to abandon their plans to manufacture cells in Germany as an example of how challenging it is. [It is reported that Bosch estimated it would cost Euro 20bn to set up a meaningful factory].

Assets to link up

Part of the government’s Grand Challenge strategy Jacqui said is to make investment decisions easier for UK companies by focusing on key long term opportunities. One way is to ensure that the assets to support this strategy – ranging from science accelerators, like Harwell Campus, the Royce Institute, Faraday, and initiatives like the new Stephenson Challenge for Motors and Power Electronics (just announced) – are linked up and pulling together [I am sure Jacqui believes the Bessemer Society is playing a valuable role here as well.]

Grid Energy

One of the ‘elephants in the room’ said a member is that the environmental benefit of an electric vehicle versus a clean diesel vehicle is not very different. The big difference is at the grid level where renewables play the main part. Rob Millar referred to a web site which shows the sources of power generated on a daily basis in different countries. The UK figure for gas for example is around 50% and coal around 10%. Jacqui looked back to when she was working at the Welsh Environment Agency and how they would never have believed it possible that renewables could account for 50% of power generation so quickly. The lesson from this is that change can happen quickly too in the battery and electric vehicle fields.

Technology breakthroughs

One member commented that while the government’s promotion of new technologies can help to prime a market, it had to be market demand and supply that generated the actual technological breakthroughs. There was then a discussion about technology breakthroughs. One member mentioned his company’s graphene transistor. The member from Reaction Engines told us about a Faraday project which involved the transfer of Reaction Engine’s ‘space-leading’ heat exchange technology to batteries. This seems to me a wonderful example of cross-fertilisation at the leading edge of science and technology.

Power Electronics

There was a lively discussion as well about the contribution of Power Electronics. One member pointed out that incremental improvements in wide band gap technology can make a big impact on efficiency. For example, a 1% improvement in efficiency from 96% to 97%, which might seem irrelevant, he said, can reduce the loss in a system from 4% of total power to 3% of total power, thus causing a 25% reduction in the heat dissipated in the dispenser. This leads to a massive improvement at the system level as the equipment can be made much smaller and operating overheads reduced significantly.

The Supply Chain

These comments prompted Andy Sellars of the Compound Semiconductor Applications Catapult in Cardiff to tell us about the work the Catapult is doing to link different parts of the supply chain – from novel band gap materials like Gallium Nitride to Power Electronics, to batteries and the whole electric vehicle supply chain. He emphasised the importance of this especially in the context of the newly-announced Stephenson Challenge.

The aim is a powerful platform

The Catapult forms part of CS Connected which is a cluster of semiconductor related companies in South Wales that could be a model for other industries to punch above their weight. In my view it is an excellent example of how joined up thinking and cross-fertilisation of ideas can help the UK build a powerful supply chain platform. I sense the same desire for more linked up collaboration at all of the regional dinners we have held this year. It was therefore an excellent note on which to end the dinner ahead of our AGM Dinner on November 20th when we give our Lifetime Fellowship Award. I hope you can join us then.

PRE-DINNER DRINKS

REMINDER FROM INNOVATE UK

Q&A FROM THE BACK OF THE ROOM

END OF DINNER CONTACTS START

SPEAKERS AND ORGANISERS

L to R: Jacqui Murray (Innovate UK); Stephen Bennington (Bessemer Society Oxford); Neil Morris (Faraday Institution); Graeme Purdy (Ilika plc); Rob Millar (Williams Advanced Engineering Ltd); Angus Horner (Harwell Campus); Alex Stewart (Bessemer Society).

ACKNOWEDGEMENTS

The organisation of the dinner was made possible with the support of the Faraday Institution, Harwell Campus, and our Annual Sponsors.

Alex Stewart

November 14th 2018